WELCOME TO LUCKY MOGUL

Welcome to Lucky Mogul, your premier destination for innovative flexible plastic packaging solutions! Step into a world where creativity meets functionality, where every package tells a unique story of quality, durability, and sustainability. Explore our wide range of customizable packaging options designed to elevate your products and meet yourspecific needs.

Whether you’re in food, pharmaceuticals, or consumer goods, we’re hereto partner with you in shaping the future of packaging. Let’s embark on a journey together, where possibilities. are endless and excellence is guaranteed.

WHAT WE OFFER

EXTRUSION

Our system is enhanced extrusion

technology and equipment that

enables us to produce monolayered

and multi-layered films of the highest quality,

durability and strength.

BAGGING

Innovative products are at the heart

of Lucky Moguls operations, and our

system in cutting-edge bag-making

equipment and allows us to deliver an

expansive range of solutions to our clients.

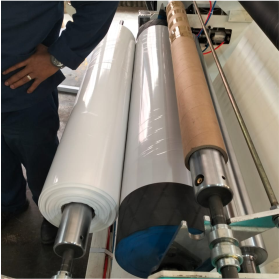

SLITTING

Our high-speed reel-slitting

equipment allows us to slit up to

500 meters per minute.

PACKAGING

Quality picture graphics to be applied to

any packaging or film. Our high-tech six-colour

flexographic printing.

WHY USE US

At Lucky Mogul, we’re more than just a packaging manufacturer – we’re your partners in success. With a legacy of excellence and a commitment to innovation, we specialize in crafting flexible plastic packaging solutions that redefine industry standards. Backed by expertise, technology, and a passion for sustainability, we’re dedicated to exceeding your expectations every step of the way.